What’s a shredder?

The shredder takes plastic waste (milk bottles, water bottles, caps, plant pots, straws, cups and cutlery…) and chops it down to small particles that can be use later in the other machines.

What can you make with it?

Nothing directly, but you will use the shredded plastic waste in the other machines to melt them into new products. If your plastic waste is bulky this is a great way to reduce the volume it takes.

What do you need to work with it?

- Plastic waste

- Electricity (we have manual and pedal powered versions in development ! )

- Boxes or bins to store the shredded plastic

How can you get a shredder?

- If you want to buy one, our parent company Singular MARS can design and build a motor, manual or pedal powered shredder to your specifications, or even parts if you want to build one yourself. If you’re interested in buying or renting one of our shredders please get in touch to get a personalized quote. Guide prices are: (delivery not included. Parts in stainless steel. Made to order, so it’s possible to adjust specs to your budget)

- Parts for self-build – PLEASE ENQUIRE .

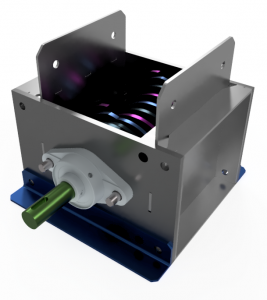

- Shredder sub-assembly unit – Starting from £599

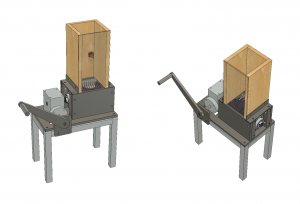

- Manual shredder – Starting from £2699

- Pedal powered shredder – Starting from £3199

- Motor powered shredder – Starting from £3499

- You can rent one from us: PLEASE ENQUIRE . Dependant on length of rental and distance from our workshop in Brighton.

- We can also shred your plastic waste as a service. You send it to us and we’ll shred it for a fee depending on how long it takes / how much it is. PLEASE ENQUIRE

- Discounts available for charities, schools and social enterprises thanks to our Patreon crowdfunding. And remember, our PATREON supporters get a discount too!

| Shredder sub-assembly | Manual (hand cranked) shredder, stand-alone |

|

|

| Motor shredder, 1.5 kW single phase, stand-alone |

Manual (hand cranked) shredder, bench-mounted |

|

|

| Pedal+Motor shredder, stand-alone |

Your next project ! |

|

? |

FAQ

- What plastics can it shred?

- While these machines are very capable of shredding a multitude of different materials, like 3D printing waste, domestic plastic waste, flip flops, bottles, thick cardboard, etc. (much more capable than a garden shredder or a kitchen blender!) they are still a light duty, budget machine, so they are NOT designed to be able to shred thick plastics (depending on type, thicker than 3-5 mm), hard plastics (thick acrylic, thick polycarbonate or ABS), bags (they tangle in the blades, heat up and melt), textiles (they tangle), etc.

They are also limited in the throughput: they are not very fast, they can’t be forced to shred too much at once or they may jam. And also, even if a type of plastic is “easy” to shred, like for example a plastic bottle, their shape may sometimes present a challenge: Sometimes there are shapes and geometries that simply will be dancing, bouncing and jumping over the blades, refusing to get caught by them. This can sometimes be solved by adding more bottles into the hopper so that they push the unlucky one into the blades, but we’ve also come up with a push stick to safely and manually push a reluctant piece of plastic down.

This is just a disclaimer to warn about the capabilities and the limitations of the equipment. If you are a DIY plastic recycling enthusiast, these machines will probably exceed your expectations. But if you are a larger company or if you are looking to shred many kgs, or tonnes of waste monthly, then you probably need an industrial, heavy duty shredder. If in doubt feel free to ask us if your material is shredable, we’ll be glad to help and trial it for you.

- While these machines are very capable of shredding a multitude of different materials, like 3D printing waste, domestic plastic waste, flip flops, bottles, thick cardboard, etc. (much more capable than a garden shredder or a kitchen blender!) they are still a light duty, budget machine, so they are NOT designed to be able to shred thick plastics (depending on type, thicker than 3-5 mm), hard plastics (thick acrylic, thick polycarbonate or ABS), bags (they tangle in the blades, heat up and melt), textiles (they tangle), etc.

- How much / how fast can I shred?

- As explained in the previous question, this will depend heavily on the material. Some materials and geometries are ideal for a quick shred, specially if they are brittle plastics. Other materials will need more persuasion or may jam frequently which will require more frequent stops.

The size of the flakes that you want to make will also have an impact. If you are okay with a rough shred, we usually do a pass without a sieve as it makes it faster. But if you require a small size of flakes, it will need a second pass and longer time.

Additionally, if you have different colours that you want to shred separately, the machine will need a bit of cleaning in between colours, to avoid contamination. Same if you have different types of plastic.

All these factors considered, as a rough reference, we have been able to achieve 1-4 kg/h with a 1.5 kW single phase shredder (blades move at 70 rpm and with 170 Nm of torque). We are able to design a higher spec machine for you, just enquire at our email.

- As explained in the previous question, this will depend heavily on the material. Some materials and geometries are ideal for a quick shred, specially if they are brittle plastics. Other materials will need more persuasion or may jam frequently which will require more frequent stops.

- Do you build the “Precious Plastic Shredder Pro”?

- We haven’t yet and we’ll “never say never”, however we believe that if you do need that much power, you’re better off buying a second hand industrial grade granulator, as fabricating the Shredder Pro could get quite expensive.

- We haven’t yet and we’ll “never say never”, however we believe that if you do need that much power, you’re better off buying a second hand industrial grade granulator, as fabricating the Shredder Pro could get quite expensive.

- Do you ship internationally?

- It depends. We’ve done it in the past, but as a small company, impacted by Brexit, sometimes it is hard to pass through all the bureaucratic hoops. Plus we believe you should be able to find more local manufacturers to avoid unnecessary carbon emmissions. Make sure to check the Precious Plastic map to see if there are other workshops around you. In addition to this, sometimes the shipping of heavy equipment like this can be too expensive for customers. But if you’re interested feel free to ask us if we can help you.